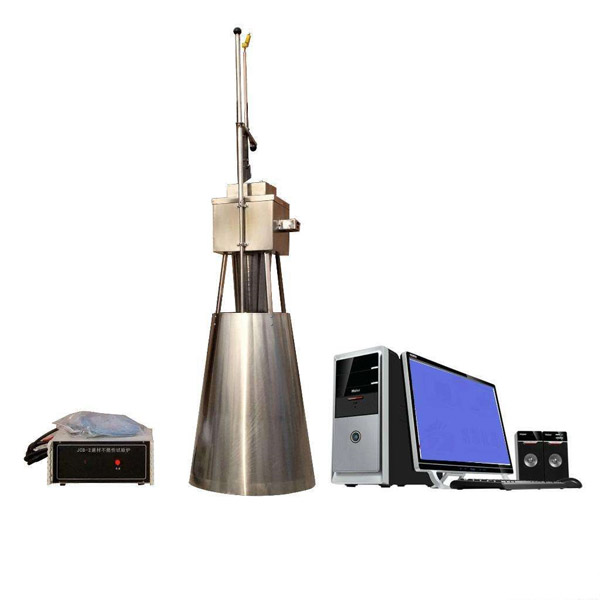

Non-combustibility Tester

Non-combustibility Tester of Building Materials for Noninflammable Material

Product introduction of the Non-combustibility Tester

The EN ISO 1182 Non-combustibility test is one of the series of Euroclass test standards. This test specifies a procedure for determining whether or not a material will contribute directly to fire development and is relevant to classification of all building products (including floorings) into classes A1 and A2.

Product parameters of the Non-combustibility Tester

| The maximum temperature | 900 ℃ |

| Temperature accuracy | ± 0.1 ℃ |

| Specimen size | Φ 45, high 50 ± 3mm |

| Weight | 45kg |

Product Feature and Application of the Non-combustibility Tester

1.Non-Combustibility Furnace measures incombustibility and combustibility of uniform building material and non-uniform building material of actual element.

2.The evaluations (results) are rising temperature in the furnace, basic mass loss and ignition of specimen.

3.Single Zone Furnace operable at up to 900 ℃ with the Kanthal Ribbon Heater.

4.750±5℃ temperature automatically control by PID and Power controller.

5.Provided with stabilized voltage supply for more quick temperature stabilization.

6.Equipped with 3 thermocouples, for temperature in furnace, specimen center, and specimen surface respectively.

7.360 degree rotatable and height adjustable thermocouple scanning device.

8.Inner furnace thermocouple device to calibrate the temperature of furnace.

9.Testing results include Mass Loss(g) and Rate(%) 、Ignition Time(s) and Sustained Flaming(s) 、Initial & Maximum Furnace Temperature(℃) 、Final Furnace Temperature(℃) 、Maximum Specimen Center Temperature(℃) 、Final Specimen Center Temperature(℃) 、Furnace Temperature Rise(℃) 、Specimen Center & Surface Temperature Rise(℃).

Application:The non-combustible test furnace is developed according to ISO 1182 and GB/T 5464 non-combustibility test method for building materials. It is mainly used in the non-combustible test method for building materials and is suitable for testing the burning performance classification of Class A fireproof materials in the burning performance classification of building materials GB8624. The non-combustible test furnace can be applied to composite products as well as to the materials of the components constituting the product. The test instrument can also be used for BS 476-4 & 11 and IMO FTP Part 1 standards in the UK. Fire testing of building materials, railway locomotive materials, and non-metallic products of ships.

Product Details of the Non-combustibility Tester

1. Adopt automatic design scheme, use PID temperature controller and thyristor technology, adjust the temperature of the furnace body and stabilize the temperature of the furnace body by reasonable switching between temperature controller and power controller;

2. The whole temperature balance mode has been improved and optimized on the basis of the UK FTT non-combustible test furnace. It can be automatically switched from the PID temperature control mode to the power control mode without the user's manual intervention. It is reasonable to control the temperature and strict. Compliance with test standards;

3. The radiant furnace is heated to 750±5 degrees by the resistance band wound around the outer wall of the radiant tube, and the sample is tested by the thermal radiation sample. The resistance band provided by Mordes is the Swedish Contaire product, which has a longer length. Service life

4. In the non-combustion furnace of building materials, the thermocouples in the furnace, the sample center and the sample surface are separately placed. The thermocouple is the US OMEGA product, which has a longer service life. The temperature of these three points is monitored separately, and the following indicators can be detected. : average temperature rise in the furnace, average temperature rise of the sample surface, average temperature rise of the sample center;

5. Equipped with the thermocouple in the furnace, the temperature in the furnace can be calibrated according to the test standard. The test device is equipped with a measuring instrument that moves up and down to adjust the thermocouple in the furnace to the required height. At the same time, in the computer software. The average value of each point can be calculated to obtain a standard temperature curve.

6. It is equipped with a 360-degree rotating and adjustable thermocouple scanning device, which can calibrate the furnace wall temperature and is equipped with test software to check whether the furnace wall temperature meets the standard requirements;

7. Stainless steel inverted cone air stabilizer and cylindrical shroud, are treated with Teflon to avoid the test of smoke erosion;

8. The heating rate is controlled by the test software, and the temperature of the furnace body can be controlled in stages, so that the radiant furnace has a longer test life;

9. Data acquisition and analysis software software, can automatically output test reports through the computer.

Standards:

BS:BS 476-4

ISO:ISO 1182

EN:EN 13501

IMO:FTPC Part 1

Dimension:

Furnace: 400 mm (W) x 400 mm (D) x 1200 mm (H)

Control Unit: 530 mm (W) × 270 mm (D) × 280 mm (H)

Weight:65kg

Installation requirements

Electrical: 110V AC 60Hz / 230V AC 50Hz, 10A

Ambient Temperature: Operating 10°C to 35°C

Dimensions: 400 mm (W) x 400 mm (D) x 1200 mm (H)

Control Unit: 530 mm (W) × 270 mm (D) × 280 mm (H)

Installation space: floor-standing fume hood