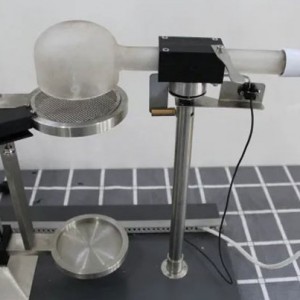

Dripping Test Apparatus

Dripping Test Apparatus Thermalmelting Materials with Stainless Steel Heat Radiator Bracket

Product introduction of the Dripping Test Apparatus

The Dripping Test Apparatus is developed according to the French building materials and railway vehicle flame retardant test standard NF P92-505, and meets the requirements of the European Union 95/28/EC automotive interior materials fire test standard; the principle of the test is through the upper The radiant heat source performs 30 KW/m2 of heat radiation on the sample, which may cause combustion of the released gas, thereby observing whether the sample will produce droplets and causing combustion of the fiber cotton.

Product parameters of the Dripping Test Apparatus

1. Stainless steel heat radiator bracket, can be rotated 90 degrees, easy to test quickly;

2. Equipped with a sample distance thermal radiation device height gauge, easy to adjust the test height;

3. Epiradiator heat radiation device, can provide 30KW / m2 heat radiation flux;

4. The panel displays the operating power value of the heat radiation device, eliminating frequent calibration procedures;

5. The power controller controls the radiation output and can adjust the radiation flux of the heat radiation device;

6. Equipped with sample and cotton tray, height adjustable and easy to evacuate the radiation source.

Product Feature and Application of the Dripping Test Apparatus

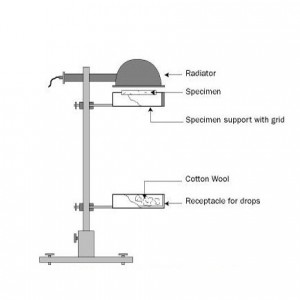

1.The dripping test apparatus comprises the following elements put together on a common base :

2.At the upper part of the first stand is placed the epiradiator-type heat radiation source of 500 W power rating, which radiant surface is made of a translucent vitreous fused silica disk of 100 mm diameter.

3.A movable handle device allows to slightly lift up the epiradiator support to rotate at 90° in the horizontal plane, in order to remove it from the test piece.

4.The second stand bears an adjustable in height assembly with at the upper part the test piece support and at the lower part the drop receptacle, these two parts being 300 mm apart.

5.The test piece support is made of a metal ring on which lies a plane circular grid in stainless steel wire.

6.The drop receptacle is composed of a small dish which flat bottom is entirely covered by cotton wool.

7.A guiding mark bound up with the epiradiator support and a graduated metal rule fixed to the pole of this second stand allow to adjust the distance between the radiant surface of the epiradiator and the upper face of the test piece.

Application: It is used for thermalmelting materials for which some inflamed or not dripping, produced by a heating source, were noticed during the main test.

Product Details of the Dripping Test Apparatus

The dripping test according to NF P 92-505 is a reaction to fire complementary test for M classification of building and fitting materials. It is used for thermalmelting materials for which some inflamed or not dripping, produced by a heating source, were noticed during the main test. This one can be either the electrical burner test for flexible and thin materials (NF P 92-503), or the radiation test (epiradiator cabinet) for rigid or flexible and thick materials (NF P 92-501).

In principle, cotton wool inflammation at the dripping test leads to M4 classification. If the cotton wool is not inflamed at the dripping test, the classification obtained at the main test is maintained or the material is downgraded according to whether there was some uninflamed or inflamed dripping during this same main test. In case of holing without inflammation or with short time inflammation at the main test, this outline is also applied to the complementary flame persistency test (NF P 92-504) when there was again some uninflamed or inflamed dripping during this complementary test.

Standard:NF:NFP 92-505

Dimension :520mm(W)X 650mm(H)X 350mm(D)

Weight:29kg

Installation requirements

Electrical: 110 to 230 V 10 Amps

Ambient Temperature: Operating 10°C to 30°C