Whether in flight or on the ground, fire is always one of the most dangerous threats to aircraft.

Therefore, in order to ensure the safety of air transportation, it is necessary to improve the understanding of the danger of aircraft fires; understand the causes of aircraft accidents and fires and the characteristics of aircraft fires, and master the methods of aircraft fire prevention.

BSS 7239 Aviation Material Toxicity Testing Device-Test Overview

The fumes from the pyrolysis and combustion products of combustibles contain a large amount of toxic gas components. When these product gases accumulate to a certain concentration, they will cause poison to the human body. Therefore, the toxicity of smoke and the thermal effects of fire constitute two key factors in fire risk assessment.

BSS 7239 analyzes the amount of gas produced in a specific smoke box using standard smoke generation test methods.

For the analysis of BSS 7239 toxic gas, the test device is in accordance with ASTM E 662 standard, and the test mode is two modes: open flame and unopen flame.

BSS 7239 Aviation Material Toxicity Testing Device-Test Requirements

The following gases are required to be measured by this standard

- Carbon monoxide CO

- Hydrogen fluoride HF

- Hydrogen chloride HCl

- NOx

- Sulfur dioxide SO2

-HCN, etc.

Difference between BSS 7239 and BSS 7238

BSS 7239 measures the content of smoke toxic gases generated during the combustion of materials, while BSS 7238 measures the content of smoke density generated during the combustion of materials. Among them, BSS 7239 analyzes the content of toxic gases by means of smoke generation, and BSS 7238 measures the content of smoke by measuring the attenuation of the light beam.

Recommend Aviation Material Device:

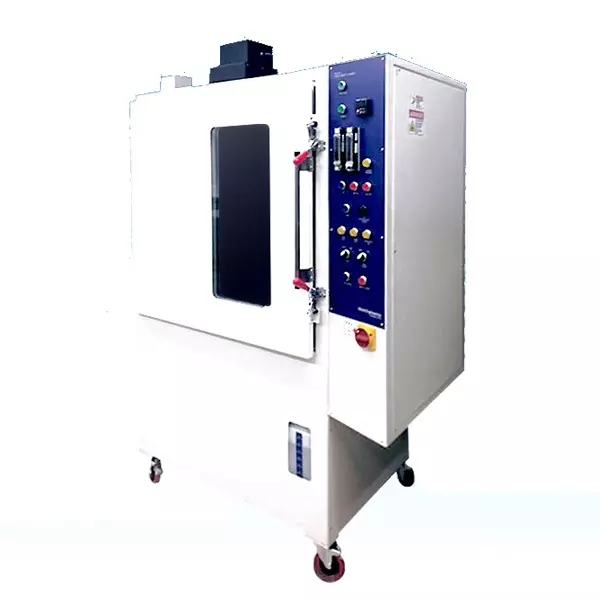

SKLINE SL844 Aviation Material Toxicity Testing Device and

SL838 Smoke Density Chamber

Performance characteristics

1. Suitable for Boeing and Airbus smoke toxicity test requirements, for collecting smoke density test box smoke;

2. Equipped with four gas interfaces, it can be used with smoke density test box at the same time.

3. Equipped with gas switch valves, pressure gauges, flowmeters and other devices;

4. Vacuum acquisition mode is adopted in the box, which is convenient for users to use.

Parameters

| Size | 1560 mm (W) x 2220 mm x (H) x 1060 mm |

| Weight | 190KG |

| Standards | AITM 2.0007A,AITM 2.0007B,AITM 3.0005、BSS 7238,BSS 7239、FAR PART 25 APPENDIX F Part V |

| Application | Aviation |

| Electrical | 110V AC 60Hz / 230V AC 50Hz, 15A |

| Ambient Temperature | Operating 10°C to 35°C |

Features

Powder coated liner removable for repair/replacement. Powder coated exterior.

Large tempered double glazed door for easy viewing and cleaning.

PID temperature controller for constant furnace setting.

Coil type tubular radiant heater with integrated thermocouple. Master electrical shut-off switch with maintenance lockout. Pneumatic actuated test sample transport system for repeatability of tests.

Electronic ignition system.

Calibrated flowmeters Propane and air flow measurement. Master gas on/off control with safety latching circuit to prevent gas flow following power interruption.

Post time: Mar-26-2020