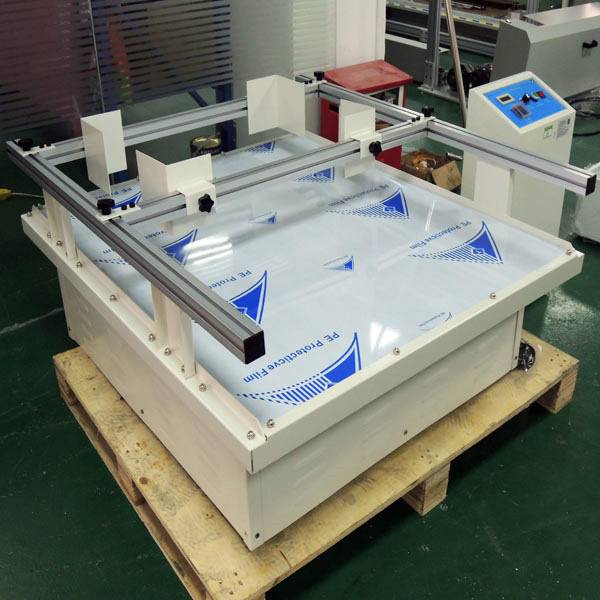

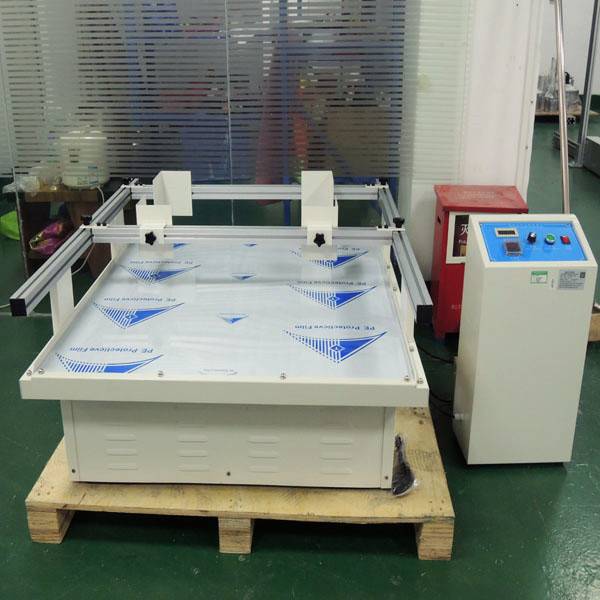

100kg Transportation Vibration Tester

100kg Environmental Test Chamber Transportation Vibration Test For Package Test

Product introduction of the Transportation Vibration Tester

Universal Vibration Test Machine/Simulated Transport Vibration Tester is applied to test the vibration-resistance of packed Toys, electronics, furniture, gift, ceramics, equipment, etc., under simulated transport conditions, according to American and EU transport standard (ASTM,IEC).

Product parameters of the Transportation Vibration Tester

|

Vibrating frequency |

100-300rpm |

|

Vibrating range |

25.4mm(1") |

|

Timer |

0-99999 hour |

|

Vibrating manner |

Rotary (positives type)turn |

|

Maximum load |

100kg 300kg 500kg 1000kg |

|

Effective area of table |

110 X 98CM 130 X 120CM 180 X 150CM |

|

Motor |

1HP(750W) 3HP(2.25kw) 5HP(3.75KW) 7HP(5.25KW) |

|

Dimemsion |

120 X 110CM 140 X130CM 190 X 160CM |

Product Feature and Application of the Transportation Vibration Tester

Simulation products in transportation state of environmental assess product packaging design, the rationality and structure strength.

1. Vibration frequency digital display, high precision

2. Synchronous silent belt drive, low noise

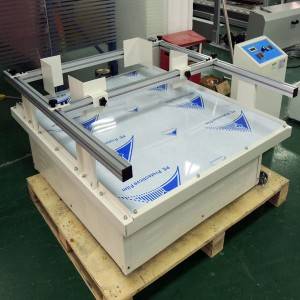

3. The sample holder adopts rail type, which is easy to operate.

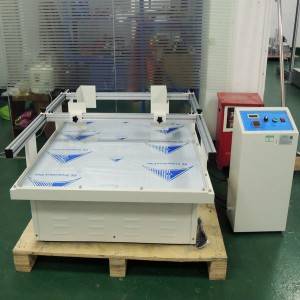

4. Heavy-duty channel steel base with shock-absorbing rubber, easy to install, strong load, stable operation

5. According to the reorganization of similar equipment in Europe and America, rotary vibration, in line with European and American transportation regulations

6. Applicable to toys, electronics, furniture, gifts, ceramics, packaging and transportation industry to test the packaging of products

Note: When moving the machine, do not lift the aluminum around to prevent bending.

Product Details of the Transportation Vibration Tester

Test object:Packaging for shipment of the products. Test program:Will the packaging products with a certain speed vibration corresponding time. Result assessment: By vibration testing products shall promote function and appearance were damaged.

Operation method:

1. Place the test product in the center of the shaker

2. Use a wrench to loosen the nut on the positioning bar.

3. Use both hands to slap and move in parallel. After fixing the test product with the clamp, tighten the nut.

4. Check if the equipment collides with other objects (there must be 0.5 meters to 1 meter of space around the instrument)

5. After plugging in the power cord, press the "switch" button

6. The regulator accelerates from left to right (Note: the minimum speed is not less than 100 rpm, the maximum speed is not more than 300 rpm)

7. Adjust and tighten the sample, place the sample in the adjusted guardrail device, and fix the clamp test sample.

The clamping force should be appropriate to avoid pinching the sample being tested.